Blocking the Bell Port

-

Is is OK to completely block the Bell Port?

("bell port" is my name for the breath exit hole at the foot of the instrument inside the bell.)

I really need a lot more back-pressure that is provided when the bell port is completely open. If I completely block the port with my finger, there does seem to be another exit path for the air ...

There are mentions on this forum of partially blocking the bell port, but no mention of fully covering it up.

-

Hi Clint! Happy to hear you've received your Sylphyo. You shouldn't block the exit port completely as that can create too much pressure for the internal tubing. You can however block it almost fully as long as you leave a bit of space. We are in the process of making small plugs to block the exit hole which will have different pressure levels.

Let me know if you have any more questions.

Maxence

Aodyo Instruments

Aodyo.com -

Yesterday I prototyped and 3d printed a small plug that effectively reduces the output port diameter to about 2.75mm (vs 6mm out-of-the-box), which feels pretty good to me. It does increase the breath noise of the instrument a bit as the air is forced through the smaller opening, but with headphones I don't notice, and overall it seems much more consistent than the piece of tape I started with.

@Support_AODYO is there guidance on how much constriction is too much constriction?

-

@meteredsection would you be open to sharing your design? Maybe a photo? Possibly an STL file??

I will be away from my 3D printer for a while, but would be interested in a range of options for controlling flow and back pressure.

Was thinking of maybe a series of different plugs with different port diameters, possibly in different colors to keep them from getting mixed up. Alternately, a single, adjustable device, maybe with a screw-type arrangement that could be turned to change the port size.

Would be interested in how your plug sits in the hole. Hard plastic (PLA, I am assuming) my not be easy to wedge into the existing Bell Port hole.

-

I blocked the port with a piece of gaffa tape, than made a hole with a pencil, till i found i had the right adjustment.

I tried several valves from aquarium shops, found that those intrinsically have to much resistance.

With each adjustment one has to learn how to play with that: so i concluded that a valve is overkill. I used black gaffa tape.

Kind regards

Frank

-

@Clint though it's hard to see the exact shape at the bell end, I believe there is a continuous taper from the mouthpiece diameter to the output port diameter. So the idea was to create a ring of tabs that bow slightly outward. This gives just enough flex to get it in without much force, but keep it snugly in presumably without putting much deformation pressure on the tube inside due to the taper of the tube.

Fundamentally it's just three stacked rings: an outer 8.5mm diameter ring to keep it from migrating up the tube, the "plug" itself at 6mm, and a smaller ring on top of that to support the tabs and reduce the risk that they snap from too much flex. The tabs bow out 0.25mm, which is plenty to provide a snug fit. I can easily push it in by hand, but need pliers to pull it out because it's too small to grab with my fingers.

One hopefully minor issue is that water can and does pool in between the tabs; going to have to keep an eye on that. I might try a version without the middle tier, though I suspect it will pass more air. Would like to refine a bit more but happy to share the STL.

-

An outstanding design @meteredsection ! I work in OpenSCAD (a solid geometry design language), but an STL file would be very helpful as a reference.

Would you consider releasing it (maybe Thingiverse) or sharing it here? Alternately by direct email (I am at clint@goss.com) would be great ...

Thanks for this design!!

-

This post is deleted! -

https://community.aodyo.com/topic/190/qui-utilise-un-bouchon-who-uses-a-stopper

You may find this thread interesting

-

@Clint apologies for the delay, the STL is here.

This version is a little easier to remove and is probably slightly better about pooling moisture. At some point I'll probably do a V3 that's a little taller--this one is still hard to grab with my fingers, and I think it is probably best to be able to take it out to let it dry out.

-

@frank when I tried using gaffe tape I started having random dropouts - the sound would suddenly stop and I would have to stop blowing and then start again to continue. Did you have this issue?

-

@badblocks Don't block the entire hole since it creates backpressure and traps humidity! This might be why you were experiencing these issues.

-

I have no such problems, i have closed less than half.. The resistence i feel while blowing is evident but soft, and the half closure gives me both good dynamic range, and endurance, i can plat ppppp FFFFF and long notes..

The resistence is less than a sax about the pressure of a recorder piano played.

Regards

Frank

-

@Support_AODYO Thanks, yes, this was with a hole cut in the tape to get the desired level of backpressure.

-

@badblocks Are you still having this issue? Have you tried resetting or reinstalling the latest update?

-

@Support_AODYO Thank you, I have not - will try both of those things and report back, traveling today. I also have a couple of the other approaches (sponge wipes, cork) on order and will try them too.

-

I've built on the design of @meteredsection and developed another 3D-printable model, available under CC-BY at https://www.thingiverse.com/thing:4768549. I also released the OpenSCAD source code, so folks can modify the design (especially the inside diameter of the airway) to suit their breath pressure preferences.

It took me a series of 10 designs till it worked reliably and I was happy with the resulting breath pressure / airflow:

(I keep getting "Something Went Wrong While Parsing Server Response" when I try to upload images ... no idea how to get around it ... oh well, check out the Thingiverse link above)

My final design reduces the breath pressure and airflow requirements by about half.

Some things I observed along the way:

-

Grabbing the plug with your fingers to remove it can be a challenge. I made the plug extra long and included a flared foot end with four sharp nubs is designed to make it easy to remove.

-

Wind noise is an issue! Without a bell port plug, the open bell port of a stock Sylphyo produces very little wind noise. I found that beveling the internal windway channel with numerous tapered bevels noticeably reduced wind noise, but it is still can be an issue, depending on your playing situation.

-

I wrestled with a characteristic of my early designs where, as I added breath pressure, the resistance I felt did not increase smoothly. It was weird, but there were "jumps" in the amount of resistance I felt and also corresponding changes in the wind noise. Very disconcerting while playing. I also had this issue with the @meteredsection design that I printed. I am guessing it had to do with an interaction between the tabs and the top of the air channel. When I added bevels on the internal channel, the problem went away.

-

Sanding the inside of the airway does make a bit of a difference. I did light sanding with a cylindrical needle file. It seems to reduce wind noise a bit and slightly reduces breath requirements.

-

The fit of the plug as I designed it may differ depending on what materials you use and your print settings. I printed the part in PLA at 210 degrees nozzle temperature with a 0.10mm layer height.

I did do a small study of the amount of breath pressure needed with various designs. I measured the MIDI CC#02 Breath Pressure commands issues by the Sylphyo configured with Breath Settings: Minimum: 20, Range 600, Curve: Log, and Filters: Enabled. I measured through a Link into the Sylphyo Bench application running on a Win10x64 system. I measured pressure in milli-PSI using an intra-oral breath pressure meter that I used for a study in 2013. The meter is described in the Measurement section (pages 2-3) of Goss, 2013, "Intraoral Pressure in Ethnic Wind Instruments" available at https://www.flutopedia.com/breath_pressure.htm and at https://arxiv.org/ftp/arxiv/papers/1308/1308.5214.pdf.

I measured "Half Pressure" and "Max Pressure" pressure readings from the intraoral pressure meter when the Sylphyo Bench application's meter for CC#02 was showing half and full scale. All readings are in milli-PSI. The "I.D." measurements are the Internal Diameter of the air channel in that plug's design.

-

With no plug installed (bell port open) the I.D. is about 6.0mm and I got pressures of 54/96 (Half/Max pressures). For me, this is way too much pressure / airflow and I run out of breath quickly. My phrases. While playing. Became. Quite. Short. I am comparing this with Native American flutes that I typically play.

-

The @meteredsection design with an I.D. of 2.5mm (measured from my print) got pressures of 18/45. It takes very little air to reach the Half and Max MIDI CC#02 of the Sylphyo.

-

The happy medium (for me) is the final design I released. It has an ID of 4.0mm and registered pressures of 22/52 - slightly more than the @meteredsection design.

-

-

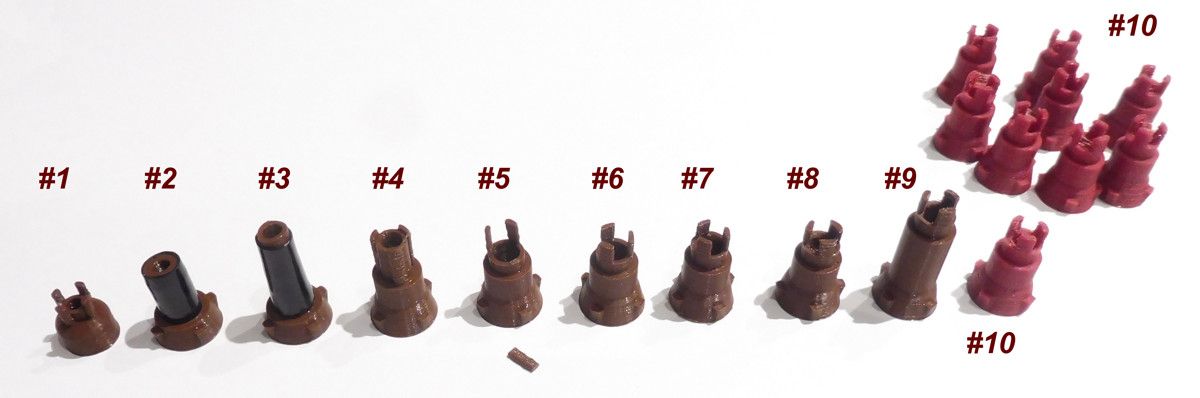

Here are the images I tried to post in the message above ...

The 10 versions, with #1 being the @meteredsection design, and the #10 (in Red PLA) being the released version.

The #2 and #3 designs used a tapered cylinder covered with heat-shrink tubing. These designs did not work so well ... the heat to shrink the tubing also melted the PLA. And, because of the taper, the tubing slipped off even after it was melted. The #5 design failed because the tabs were too slender.

The # 9 design was a test of whether a longer internal channel changed the wind noise and/or back pressure. It hardly did at all ...

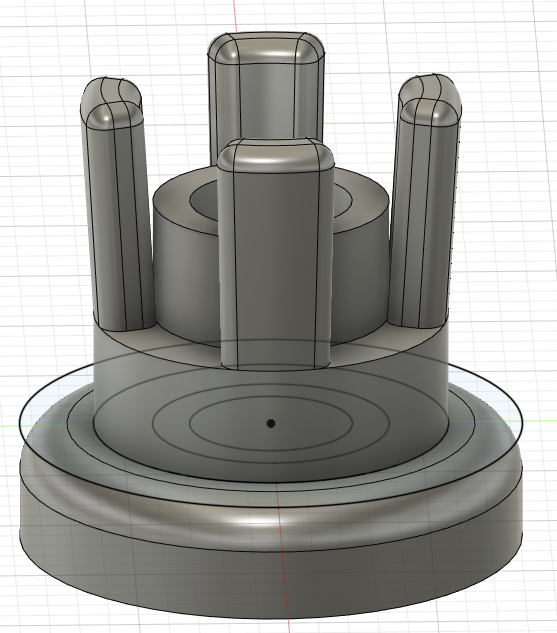

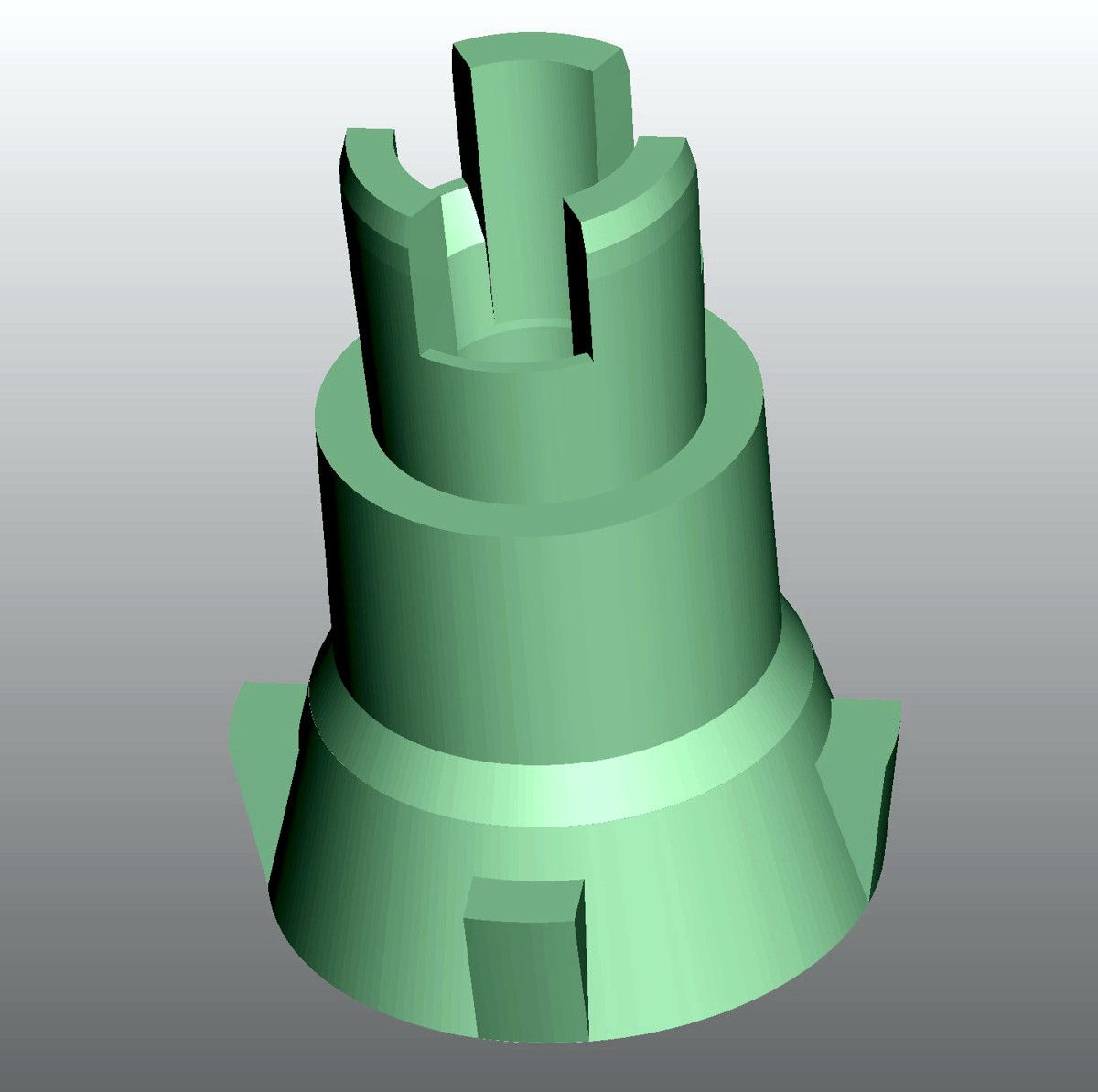

Here is a rendering of the design file as posted on https://www.thingiverse.com/thing:4768549 :

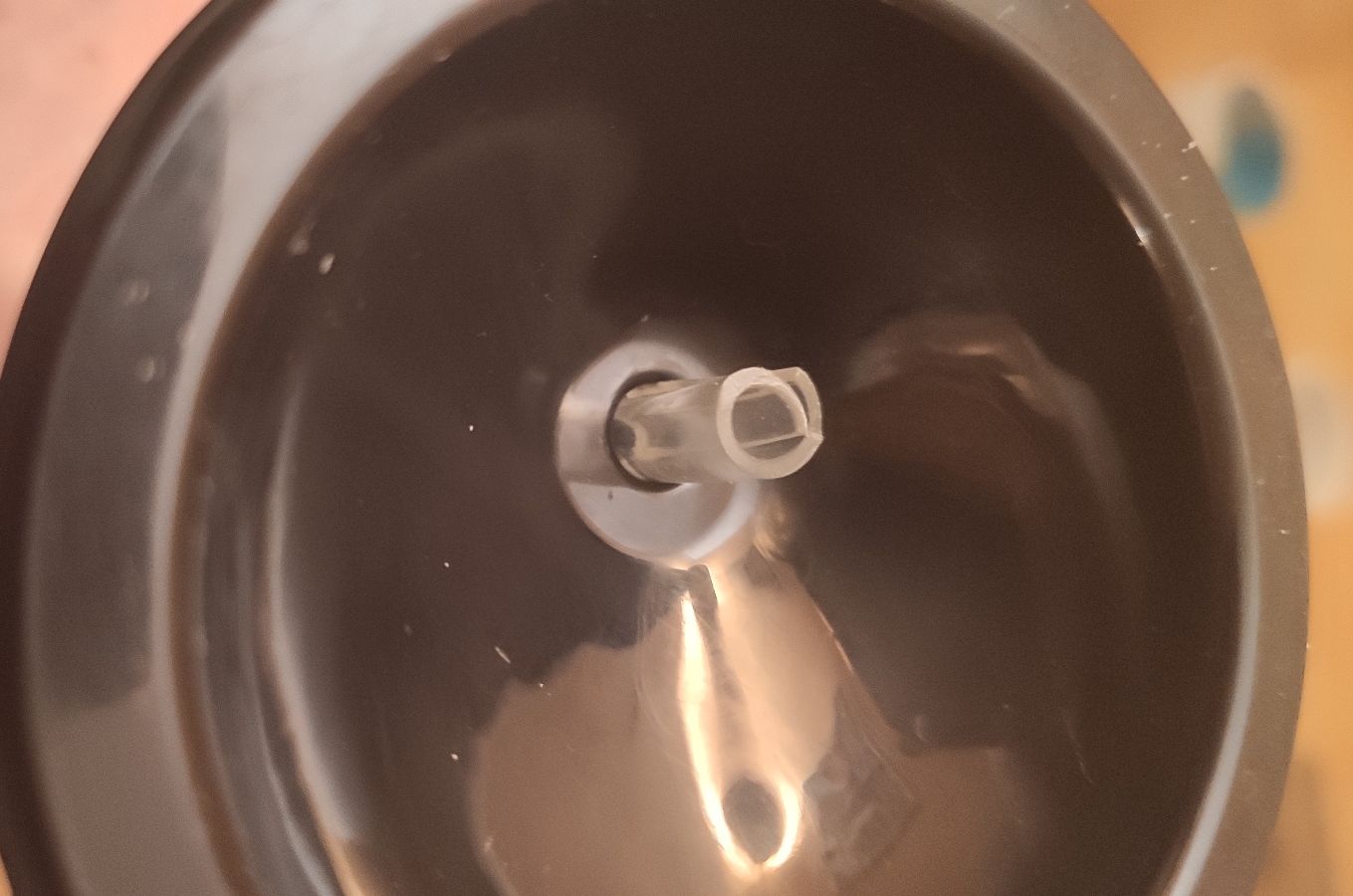

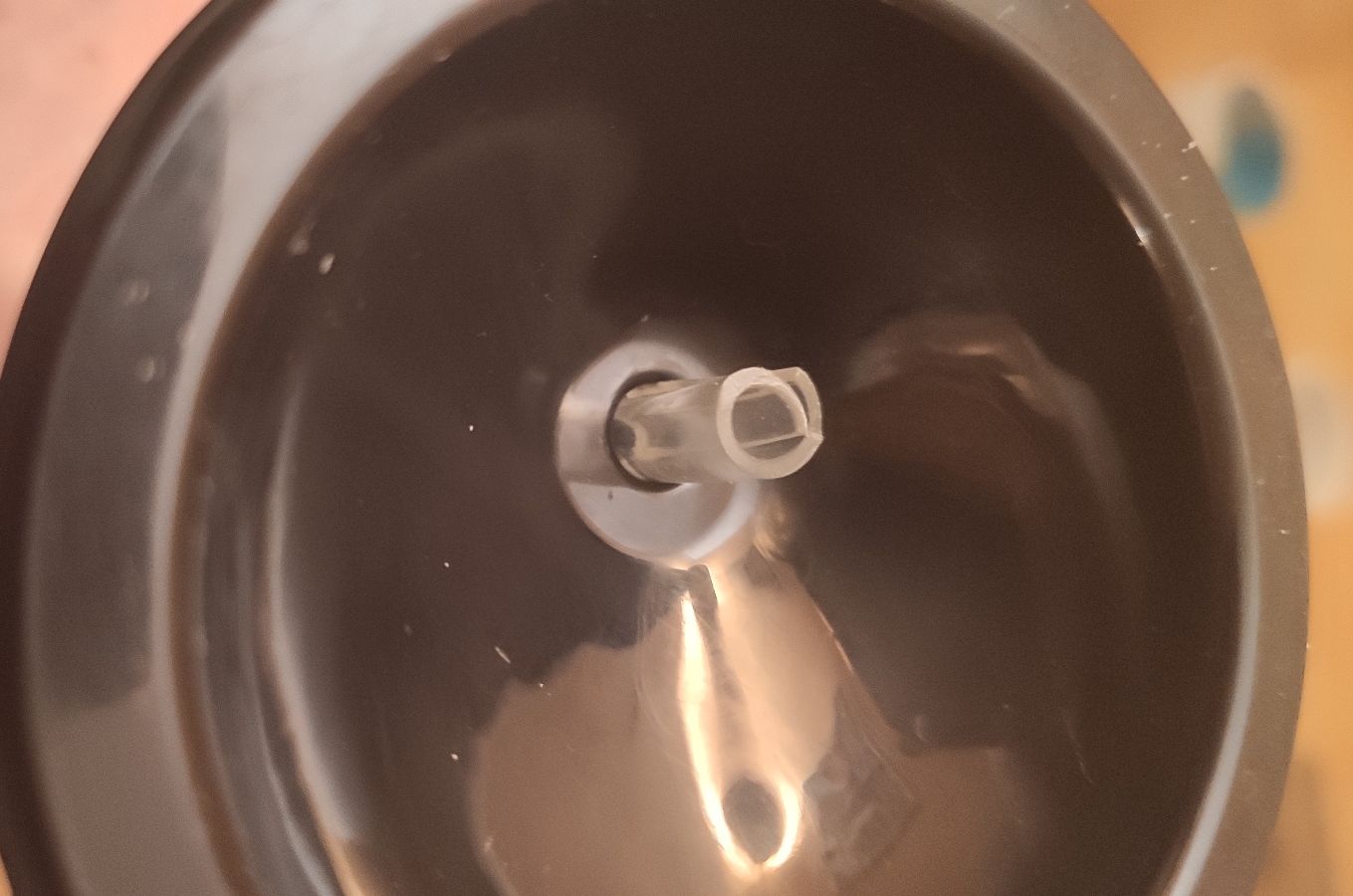

And here is the plug installed in the bell port:

-

@Clint Thanks so much for this - I had a local shop print a few and the design works like a charm. I'd actually prefer even less airflow so will probably experiment with narrowing the opening further.

-

@badblocks Great to hear!

I should really produce models with several sizes of air channels for different back pressures. The one you printed has a 4.0 mm internal channel (vs. the 6.0 mm on the Sylphyo's open bell port with no plug). That reduced the airflow by about half (I tested this with a pressure meter). I will probably do versions with 3.6 and 3.2mm internal channels ...

-

@Clint if you design them, I'll use them! :)

-

This post is deleted! -

Quand allez-vous livrer avec le Sylphyo des embouts pour régler le débit d’air ?

-

@zzrichie said in Blocking the Bell Port:

Quand allez-vous livrer avec le Sylphyo des embouts pour régler le débit d’air ?

When will you deliver tips to regulate the airflow with the Sylphyo?I am working now on an updated "Bell Port Plug" design. It will be available as a 3D Model (OpenSCAD and STL format files) in 3 different sizes for 3 different amounts of airflow and back-pressure. I will also include a detailed description of how I have been printing and finishing these plugs (post-processing with a file is very important!)

My updated version should be available in a few days ...

I believe Aodyo may also be working on their own part (which will likely make my version obsolete ... ah well!)

-

This post is deleted! -

@zzrichie nous allons annoncer quelque chose a ce sujet bientot !

-

👍 merci

-

I have just posted Version 2 of my design on Thingiverse: https://www.thingiverse.com/thing:4768549

It includes numerous improvements in fit and reliability. It also accommodates different Inside Diameter (ID) values. Three ID sizes are provided - 4.0mm, 3.6mm, and 3.2mm - resulting in progressively less airflow requirements when playing the Sylphyo.

It also includes extensive information on print settings and post-processing (filing with needle files) to get a reliable fit. I do believe that any 3D printed part will need to be carefully sanded or filed to comfortably fit into the bell port of the Sylphyo.

Feedback welcome!

I've printed in different colors to flag the Internal Diameter sizes: 4.0mm (black - about half the airflow), 3.6mm (brown - less airflow needed), and 3.2mm (red - substantially less airflow needed)

-

My life-time supply of Bell Port Plugs:

-

Definitively not at the same complexity level, nor investment, my quick & dirty solution is to use a piece of rubber hose, cut on its length, and rolled on itself, providing a reduction of section.

With changing the hose diameter, when bigger will require more turns, hence reducing even more the remaining air passage.)

The only issue is to not lose it after cleaning ! -

J'ai fait les miens avec du FIMO, très facile et économique.

-

@Clint thank you again, just got my prints...the smallest is my preference and it works a treat. I think I could go even smaller!

-

@badblocks Thanks for the feedback!

Wow ... so you prefer the most restrictive one? The one with the most back-pressure?

I just want to confirm ... and, if so, I can easily produce even more restrictive plugs ...

-

I'm following this thread carefully and I'm experimenting with tape. When I half block the bell port with tape, flutter tongue and growl don't work anymore, is it the same for you with 3D printed plugs ?

-

@David-Lazzi It should still work decently! It just takes a bit of time to get used to it. Once you are used to having something blocking the hole you will be able to do these techniques well. Growl is something interesting because it does not work well in general with breath sensors. If you manage to make it work I would be curious as to what kind of technique you are using!

Best,

-

Similar solution here. A square of softish rubber (from a dead exercise ball) rolled into a “C” shape and inserted with the open section facing downward. No pooling and very little wind noise.

@Blonk said in Blocking the Bell Port:

Definitively not at the same complexity level, nor investment, my quick & dirty solution is to use a piece of rubber hose, cut on its length, and rolled on itself, providing a reduction of section.

With changing the hose diameter, when bigger will require more turns, hence reducing even more the remaining air passage.)

The only issue is to not lose it after cleaning ! -

@Clint yes, for better or worse, I think going even a bit smaller would be beneficial - I've been an EWI player for a decade so I'm used to a lot of back-pressure and a very narrow airstream.

-

@David-Lazzi Sadly, I am flutter-tongue-challenged**, so I can't test that.

On my instruments (mostly Native American flutes) my approach to growling is to hum. However, unlike the way sax players growl, I typically hum the same notes as I am playing. (It's easy - essentially a "sing what you play" exercise.)

On real-world Native flutes, prominent humming produces an "effect" that you might use only occasionally. However, very quiet / slight humming can be used more generally to control the timbre of my sound.

On real-world flutes, I suspect that the humming vibration cross-breeds with the resonant air column vibration in the flute's sound chamber to produce a complex vibe-child. For reed instruments, maybe the mechanism is different ... maybe it alters the way the reed responds??

On wind controllers with pressure sensors, I imagine that the sensor is rapidly responding to pressure changes and sending those changes at whatever rate the singles are configured (and certainly capped by the 31.25 kHz MIDI bitrate).***

It seems to me that the sound you get is based on how your sound generator responds to that stream of breath changes.

My setup parameters are:

- MIDI Mapping => Breath => Breath Rate = Medium (250Hz)

- Breath => Curve = Log

- Breath => Filtering => On

- (not sure what other parameters are relevant)

... and I have not (yet) tried any other settings

My experience with those setting on sampled-based virtual instruments (I'm mostly using Kontakt instruments I've recorded and constructed using Unisono - Portamento) humming does not work well. I get a stuttering effect that is not particularly useful (to me).

On physical modelling engines such as Respiro, the results seem to be much more useful. Of course, Respiro is not modelling real-world instruments but instruments that really are virtual, so there is no set standard. But to me, some of those instruments do produce effects with humming that do seem cool!

** I have a "tied tongue" - a connection on the bottom of my tongue to the floor of my mouth that prevents me from flutter tonguing. It is a tradition at our workshops that our student will flutter tongue at every opportunity as a joke.

*** Does the 31.25 kHz MIDI Baud rate also apply to MIDI over USB?? I can't find a source that addresses this ...

-

@badblocks I have just uploaded three more STL model files with more restrictive air channels ... https://www.thingiverse.com/thing:4768549 ... Please tell me how they work out.

The largest of my plugs should (based on the cross sectional area of the air channel) increase back pressure by a factor of 2.3, the smallest of my plugs (that I just uploaded) should increase back pressure by a factor of 6.7.

CAVEAT: I have not printed these ... but I expect they should work ...

-

@Support_AODYO OK, So I will therefore train more on flutter tongue with a piece of tape on the bell port. About the growl, you make me doubt. I sent you back the Sylphyo a couple of days ago and I can't check it. As far as I can remember, when I purr like a cat while I'm blowing, the sounds of the Sylphyo reacts very well. The Sylphyo sounds the same way like a clarinet mouthpiece, a kind of dirty but fluid sound. I'll record myself as soon as I get my Sylphyo back.

-

@Clint As soon as I started to play the Sylphyo, I tried to growl because I knew it was possible with the older generation of EWI. I don't know exactly what you mean by humming, but it seems pretty close to my method. To me it's like singing a single note but with a vibration in the throat. The pitch of the note sung varies according to the note played in order to get a clear mismatch between the vibrating note I sing and the note I play with the real instrument. To be honest, I don't know how it works with the reed. And I don't know how it works with a wind controller because it's supposed to respond to that stream of breath changes, as you wrote, and there are no mismatching notes, are there ?

By the way, it works better with the stock open hole. When I half block the hole, it's like there's too much pressure inside and the sensors aren't responding to tiny variations.

So far I mainly use internal sounds, but I plan to buy a physical modeling engines. Thanks for your answer, it seems to be a good choice to use this effects.

-

@David-Lazzi I had bad results with tape and other improvised methods - the 3d printed plugs posted here work great!

-

@badblocks Thanks for comparing, I should try a 3d printed plug.

-

@David-Lazzi I was doing pretty well with tape, but the back pressure varied every time I played (annoying), it sometimes gave way a bit and the back pressure would change, and it was mildly "unprofessional".

3D printing is easy for me, and if you have easy access to printing the parts I posted on Thingiverse, it might be worthwhile. However, I suspect the rolled-up tubing works just as well.

-

@Clint The fab lab near my apartment is closed due to COVID-19. I will have to wait a long time yet.

-

@David-Lazzi I realize that 3D printers are not yet mainstream enough for easy access for everyone. I wish we were able to produce and ship these plugs, but we are not really set up for that. One daunting issue is that many players are on the Continent and shipping to Europe for us is complex (forms and then more forms).

I have sent several samples of each of the three largest sized plugs to @Maxence822. I also believe that Aodyo is working on their own design. I am hoping that Aodyo will adopt a strategy for providing whatever turns out the be the best plugs to the community ...

-

@Clint To me it's more a question of restriction of freedoms. I like your work shared in open source, but in this context I also hope that Aodyo will offer us something.

-

@David-Lazzi Not sure of your location but I've been having good results with FacFox for small batches though they do have a minimum order size - been using their SLA Durable resin for the plugs.

-

@badblocks I would love to hear details on how other materials work with this part!

I am thinking that flexibility is a key issue. PLA is rather strong but not very tolerant of deflection - it tends to snap suddenly and with sharp edges. Something with a bit more give would be ideal ... maybe ABS? (I don't print in ABS because I don't have a good ventilation setup) ...

-

@jcfitn En attendant que les fab labs réouvrent en région parisienne, je vais certainement me rabattre sur cette méthode. Quel type de FIMO utilises-tu ? Le cône ne glisse pas malgré sa surface lisse ?